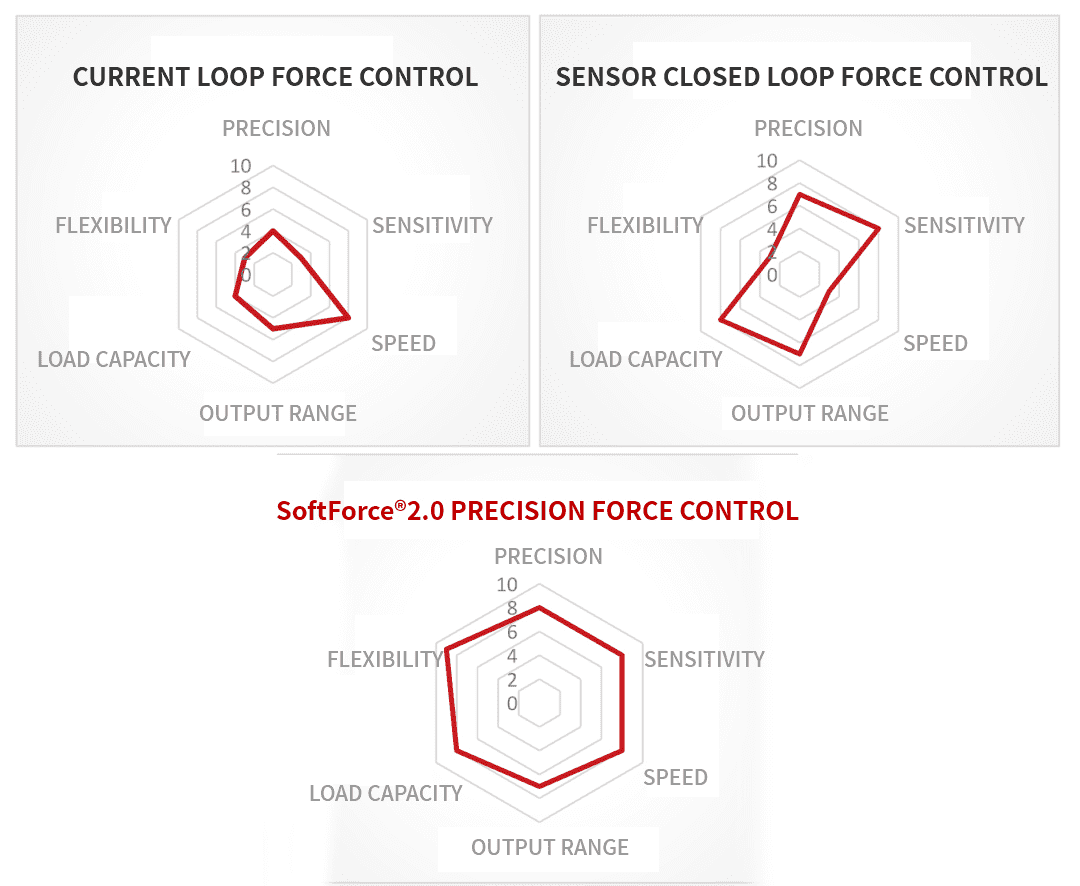

A halin yanzu, yawancin masu kunnawa a kasuwa suna da nau'ikan hanyoyin sarrafa ƙarfi iri biyu:

1. Gudanar da madauki na yanzu

Sauƙi mai sauƙi don aiwatar da hanyar sarrafa ƙarfi ta al'ada, wanda ke gane ikon sarrafa ƙarfi ta hanyar daidaita yanayin halin yanzu na motar.Amfanin shi ne cewa ba shi da wuya a aiwatar da shi, kuma yana iya samun ikon sarrafa karfi a cikin kewayon 5% -15% daidai;rashin amfani shine cewa saurin motsi yana jinkirin, ba za a iya juyawa baya ba, kuma ba zai iya biyan bukatun wasu al'amuran tare da madaidaicin buƙatun ba.Bayan lokacin amfani, lalacewa na inji zai kawo kurakurai kuma ya kara rage daidaito.

Irin waɗannan masu kunnawa yawanci ba su da na'urori masu auna firikwensin, kuma ko da akwai na'urori masu auna firikwensin, ana amfani da su kawai azaman "nunawa" na ƙarfi kuma ba sa shiga cikin sarrafawa.Alal misali, ƙara firikwensin zuwa latsa, firikwensin yana karanta girman ƙarfin, kuma yana nuna ƙimar ta hanyar mita, wanda ake amfani dashi don taimakawa wajen daidaita girman ƙarfin, amma irin wannan daidaitawa gabaɗaya ba shi da wani abin yi. tare da daidaiton karfi.

Tsarin tsari, ba ya da alaƙa da zane-zane da rubutu

2. Sensor rufaffiyar madauki iko iko

Wata hanyar sarrafa ƙarfi ita ce ƙara na'urar firikwensin ƙarfi na al'ada da al'adar rufaffiyar madauki iko algorithm.Amfanin shi ne cewa an inganta daidaito, amma rashin amfani shi ne cewa gudun yana jinkirin.Ta wannan hanyar, ana iya ƙara daidaiton ikon sarrafa ƙarfi daga 5% zuwa 1%.Idan babu daidaitaccen aiki na algorithm, ko kuma saurin firikwensin bai yi sauri ba, yana da saurin "overshoot".

Ƙarfafa Sarrafa Ƙarfi

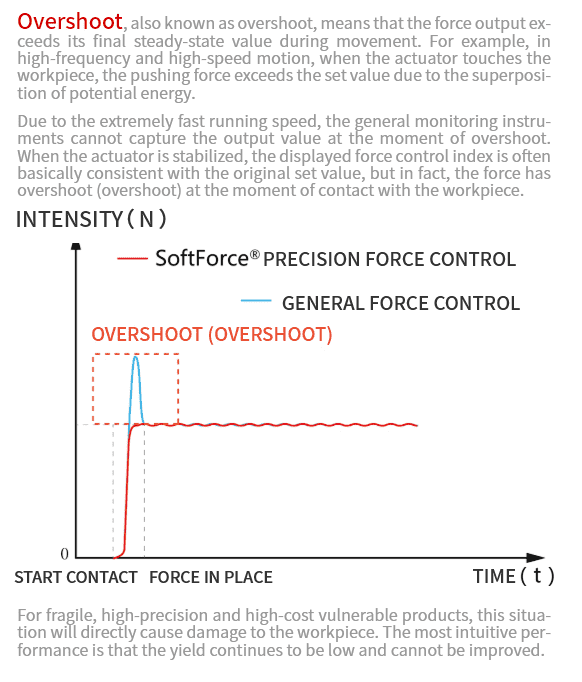

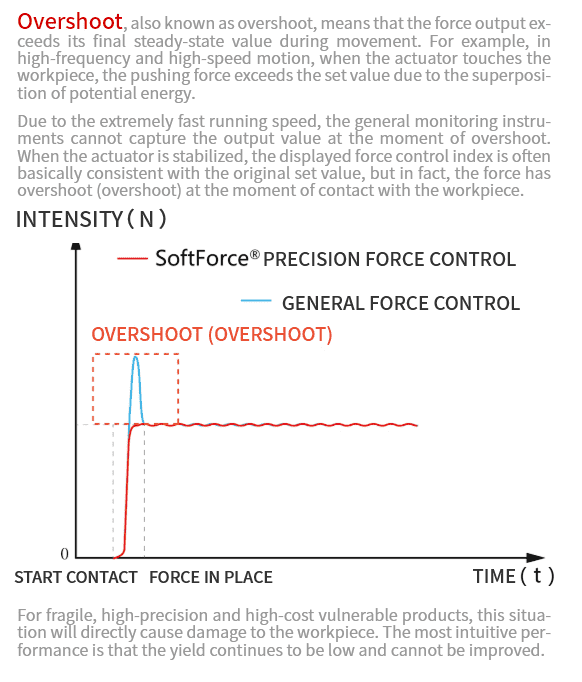

Ba makawa "overshoot"?

Hanyar sarrafa ƙarfin rufaffiyar madauki na firikwensin yana da wuyar magance ƙarfin tasiri.Mafi bayyanar da kai tsaye shine "overshoot" yana da sauƙin faruwa yayin da ake hulɗa da al'amuran da ke da buƙatun ɗan lokaci.

misali

Gabaɗaya, a cikin yanayin babban gudu da babban fitarwa, lokacin da mai kunnawa ke tuntuɓar kayan aikin galibi yana girma musamman.Alal misali, idan an saita ƙarfin turawa na actuator zuwa 10N, yana da sauƙi don isa 11N da 12N lokacin da ya taɓa kayan aiki, sannan a kira shi zuwa 10N ta hanyar sarrafa algorithm.Irin waɗannan matsalolin galibi suna faruwa lokacin da aka ƙara na'urori masu auna firikwensin ƙarfi da abin da ake kira masu sarrafa ƙarfi a kasuwa.

Wannan shine matsalar cewa saurin amsawa baya da sauri.Maɗaukakiyar saurin gudu da daidaitaccen fitarwa da kwanciyar hankali biyu ne na sabani a cikin kansu.Idan aka yi overshoot (overshoot), ainihin ƙarfin da ke wurin ba shi da ma'ana.

Musamman a cikin madaidaicin tsarin kayan aiki na taron matsa lamba, sassa masu rauni da tsada, gabaɗaya ba a yarda da wuce gona da iri.

Cikakken iko iko, babban mita da babban gudu ba tare da wuce gona da iri ba?

Ta yaya TA ke yi?

Don madaidaicin yanayin aikace-aikacen aikace-aikacen, ana amfani da hanyar "saukarwa mai laushi" don yin la'akari da buƙatun babban saurin gudu da madaidaici, wato, sarrafa iko mai ƙarfi.Mai kunnawa da sauri ya kusanci kayan aikin ta hanyar yanayin motsi, da sauri ya canza zuwa yanayin sarrafa ƙarfi a wurin da yake shirin tuntuɓar kayan aikin, kuma a hankali yana ƙara fitarwa har sai ya kai ƙimar da aka saita.Yanayin matsayi + yanayin sarrafa ƙarfi + lokacin tabbatar da ƙarfi, jimlar lokacin da aka yi amfani da shi shine ingantaccen aiwatarwa guda ɗaya na mai kunnawa.

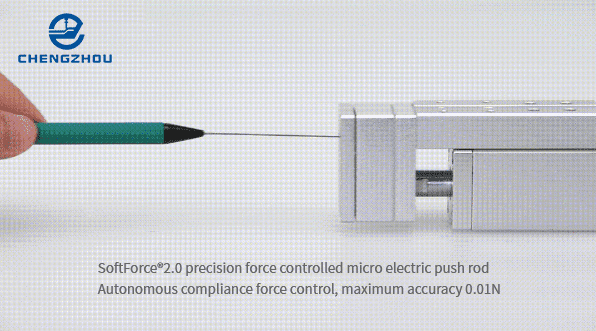

Haɗe tare da babban firikwensin ƙarfi mai sauri da ƙirar ƙididdiga mai sarrafawa na tushen ƙira, SoftForce®2.0 daidaitaccen mai sarrafa ƙarfi na iya tantance matsayin mai kunnawa da yanayin tuntuɓar ta atomatik tare da kayan aikin, ta yadda mai kunnawa, azaman ƙarshen aiki da kai. kayan aiki, yana da aiki iri ɗaya da hannun ɗan adam.fahimta tactile, sarrafawa da hankali na kisa.

A daidai wannan nisa, saurin saurin saukowa mai laushi na "SoftForce ®2.0 Precision Force Control" yana ƙaruwa, haƙuri ya fi girma, kuma yana iya cimma cikakkiyar iko, wanda ke inganta tsarin samar da kai tsaye kuma yana rage yawan farashin gwaji tabbatar da kuskure.

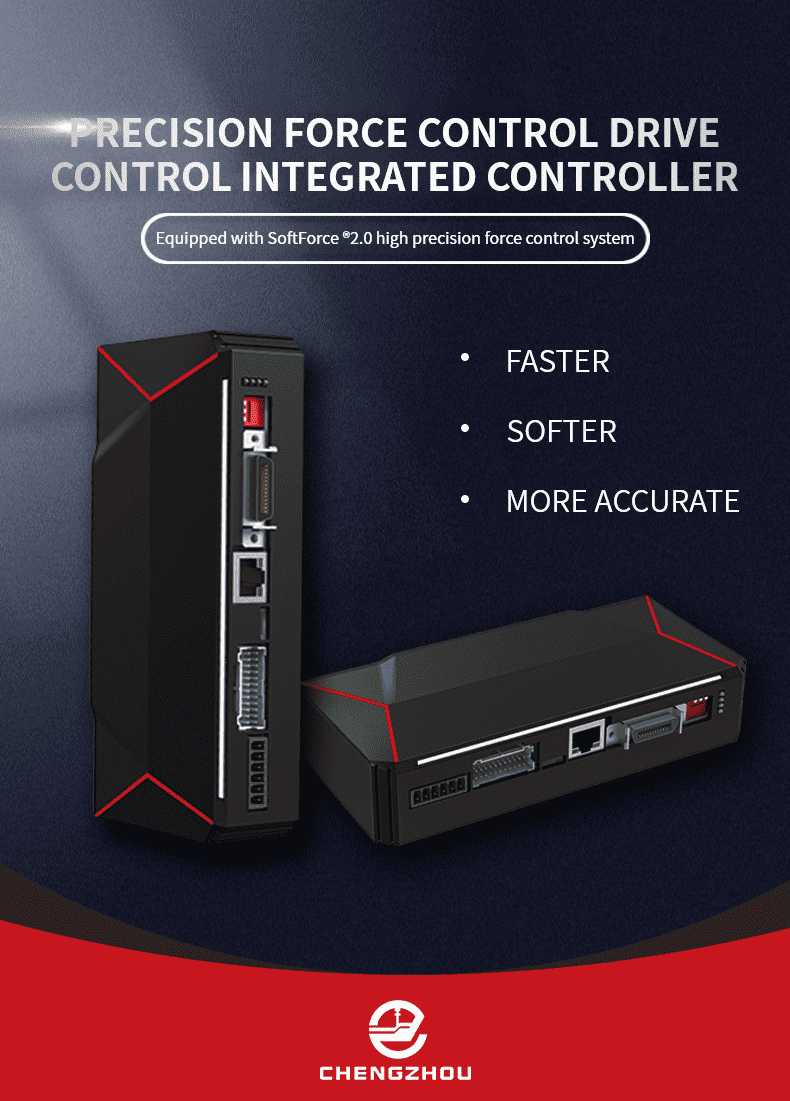

▋Yawan sarrafa mita don samun kyakkyawan aiki

Zagayowar lissafi na "Six-axis Force Sensor + Robot" tsarin sarrafa ƙarfin da aka saba amfani da shi a kasuwa shine miliyon 5-10, wato mitar sarrafawa shine 100-200 Hz.Mitar sarrafawa na SoftForce®2.0 madaidaicin masu sarrafa ƙarfi na iya kaiwa 4000Hz (watau 0.25 millise seconds), kuma ƙirar mitar mai girma na iya kaiwa 8000Hz, wanda shine sau 4-8 fiye da mitar sarrafawa na gabaɗaya mai sarrafa ƙarfin robot.

▋ Ikon iko mai yarda da aiki, wanda zai iya bin canjin ƙarfin waje

Ingantacciyar ƙimar amsawa da martanin ƙarfi nan take yana ba mai kunnawa damar amsawa nan take ga sojojin waje da cimma nasarar sarrafa ƙarfi mai ƙarfi.Ko da idan an ci karo da dakarun waje yayin aiki, ana iya daidaita shi cikin lokaci, yana sa tsarin ya zama daidai.Better kariya daga workpieces.

Babban mita da babban gudu ba tare da wuce gona da iri ba

Ko da a ƙarƙashin motsi mai girma da sauri, har yanzu yana kula da daidaiton fitarwa mai girma, kuma a lokaci guda yana tabbatar da "saukarwa mai laushi" da "babu overshoot", yana tuntuɓar sassan sassan da babban sauri, ƙananan ƙarfi, kuma yana yin sassauƙa. karba da sanya sassa, da sauransu, don guje wa lalacewa ga sassa masu laushi da masu rauni.Abubuwan da aka gyara.

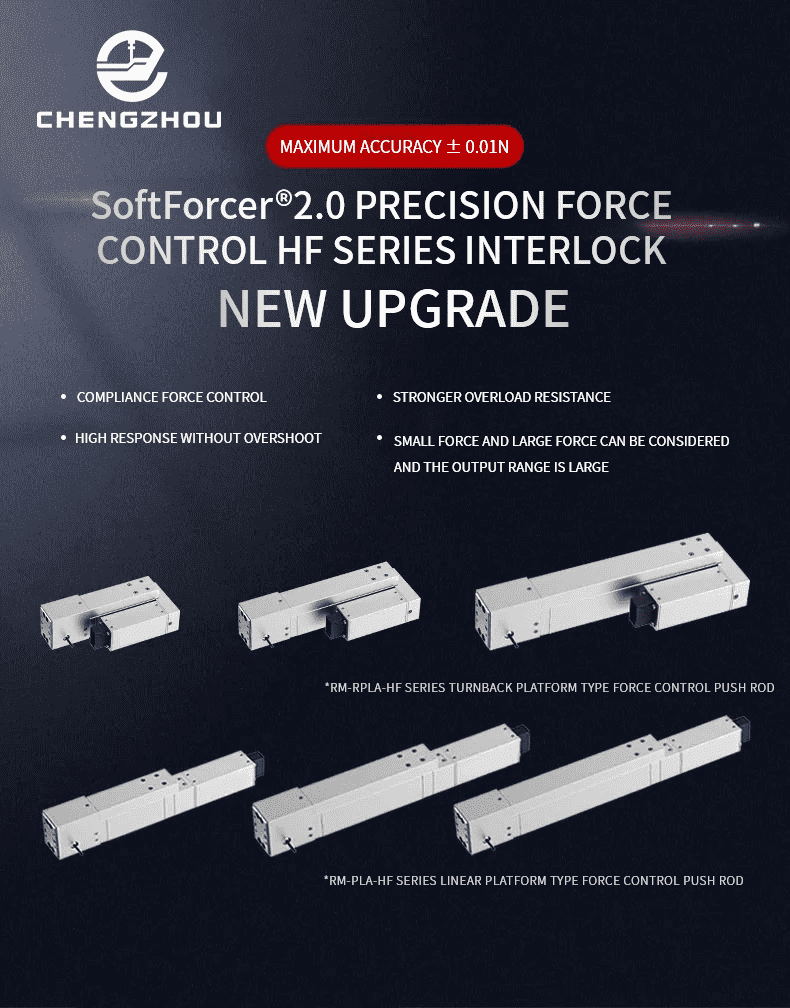

SoftForce®2.0 Madaidaicin Ƙarfin Ƙarfin

HF jerin sabon haɓakawa

▋ Ƙarfin ƙarfin hana ɗaukar nauyi

Dangane da zurfin fahimtar tsarin kan yanar gizo da yawan maimaitawa, Chengzhou sabon haɓaka SoftForce®2.0 daidaitaccen tsarin sarrafa ƙarfi na HF a cikin Fabrairu na wannan shekara yana da ƙirar firikwensin haɗe-haɗe, kuma ikon hana yin lodi ya ninka sau da yawa fiye da na cikin. baya, tare da mafi girma karko da sauƙin amfani.Yi jimre da ƙarin hadaddun yanayi.

▋ Za a iya la'akari da ƙananan ƙarfi da babban fitarwa

An sanye shi da SoftForce®2.0 babban madaidaicin tsarin sarrafa ƙarfi, madaidaicin tebur mai sarrafa ƙarfi mai ƙarfi da sandar turawa tare da babban bugun jini da babban kaya na iya haifar da ƙarami da madaidaicin ƙarfi a ƙarƙashin babban nauyi, kuma yana iya yin la'akari da ƙarfin a daidai wannan. lokaci, kuma kewayon fitarwa ya fi fadi.Ya fi girma, watau faɗaɗa ƙarfin ƙarfi mai ƙarfi*.

*Force Dynamic Range: Rabo tsakanin matsakaicin matsakaici da mafi ƙarancin ƙarfin da za a iya fitarwa.

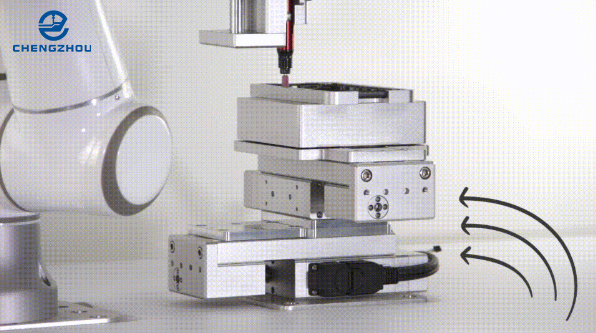

Za'a iya amfani da madaidaicin iko akan gatari guda kawai

SoftForce®2.0 madaidaicin mai sarrafa ƙarfi mai sarrafa ƙarfi ba za a iya amfani da shi kawai a cikin axis guda ɗaya ba, har ma yana ba da ƙarin dama don hanyoyin haɗin axis da yawa.Misali, sabon “RM Chengzhou 2D Synchronous Precision Force Control Platform Control System” wanda Chengzhou Technology ya ƙaddamar ya ƙunshi na'urori masu sarrafa wutar lantarki guda biyu na Chengzhou, waɗanda za su iya maye gurbin ƙarfin tsarin sarrafawa na "Six-axis Sensor + robot", ana amfani da shi don niƙa da ɓata ɓangarorin ciki na wayoyin hannu, da sauransu.

Chengzhou 2D daidaitaccen tsarin sarrafa dandali mai aiki tare

(An sanye shi da SoftForce®2.0 babban madaidaicin tsarin sarrafa ƙarfi)

Sophisticated da sauƙin amfani da sabis na ƙwararru

Algorithm na ci gaba na sarrafawa da tsari mai sauƙi yana kawo ƙwarewar mai amfani mai dacewa ga abokan ciniki.Ko da ma'aikacin da ke da ƙarancin matakin baya zai iya farawa a cikin mintuna 5, da gaske "toshe da wasa".

A lokaci guda, ƙwararrun ƙwararrun fasahar Chengzhou da ƙungiyar sabis na fasaha bayan-tallace-tallace na iya ba abokan ciniki tallafin fasaha na lokaci, cikakke kuma ba tare da damuwa ba a karon farko, ko shakkar fasaha ne, koyarwa, warware matsala ko kiyayewa.

Fasahar Chengzhou a koyaushe tana da ƙarfin gwiwa don faɗaɗa iyakokinta.Tare da ƙarfin fasaha mai ƙarfi da ƙima, ya ci gaba da ƙaddamar da ƙarin hazaka, mafi daidaito kuma mafi dacewa samfuran actuator masu inganci don samar da samfuran ci-gaba don marufi da gwaji, 3C aiki da kai, masana'anta daidaito, mai kaifin likitanci da sauran masana'antu.ainihin abubuwan da aka gyara kamar daidaitattun tsarin sarrafa motsi da masu kunnawa.

Lokacin aikawa: Mayu-31-2022